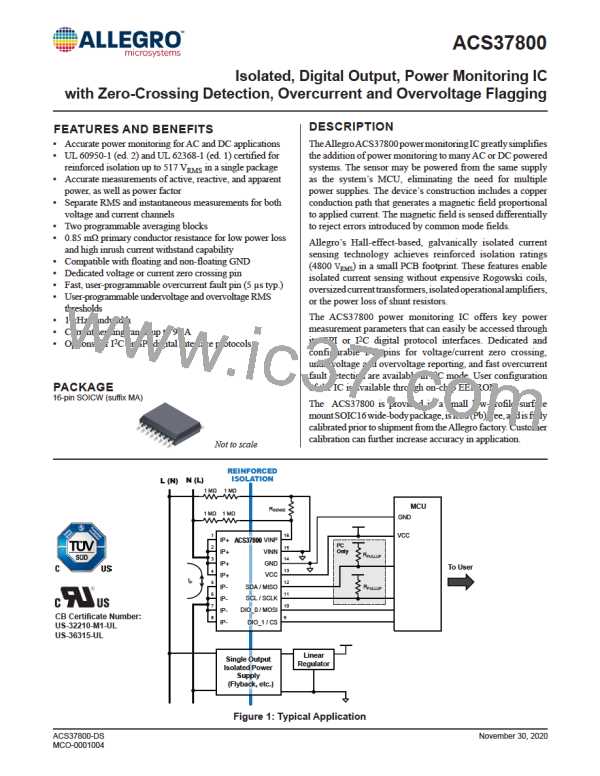

Isolated, Digital Output, Power Monitoring IC

with Zero-Crossing Detection, Overcurrent and Overvoltage Flagging

ACS37800

THERMAL PERFORMANCE

The thermal capacity of the ACS37800 should be verified by the

Thermal Rise vs. Primary Current

end user in the application’s specific conditions. The maximum

junction temperature, TJ(MAX) (165℃), should not be exceeded.

Further information on this application testing is available in

the DC and Transient Current Capability application note on the

Allegro website.

Self-heating due to the flow of current should be considered dur-

ing the design of any current sensing system. The sensor, printed

circuit board (PCB), and contacts to the PCB will generate heat

as current moves through the system.

The thermal response is highly dependent on PCB layout, copper

thickness, cooling techniques, and the profile of the injected current.

The current profile includes peak current, current “on-time”, and

duty cycle. While the data presented in this section was collected

with direct current (DC), these numbers may be used to approximate

thermal response for both AC signals and current pulses.

ASEK37800 Evaluation Board Layout

Thermal data shown in Figure 31 and Figure 32 was collected

using the ASEK37800 Evaluation Board (TED-0003306). This

board includes 750 mm2 of 4 oz. copper (0.0694 mm) connected

to pins 1 through 4, and to pins 5 through 8, with thermal vias

connecting the layers. Top and Bottom layers of the PCB are

shown below in Figure 33.

The plot in Figure 31 shows the measured rise in steady-state die

temperature of the ACS37800 versus continuous current at an ambi-

ent temperature, TA, of 25 °C. The thermal offset curves may be

directly applied to other values of TA. Conversely, Figure 32 shows

the maximum continuous current at a given TA. Surges beyond the

maximum current listed in Figure 32 are allowed given the maxi-

mum junction temperature, TJ(MAX) (165℃), is not exceeded.

140

120

100

80

60

40

20

0

0

10

20

30

40

50

60

70

Continuous Current ꢂꢅꢄ

Figure 31: Self Heating in the MA Package

Due to Current Flow

80

70

60

50

40

30

20

10

0

Figure 33: Top and Bottom Layers

for ASEK37800 Evaluation Board

25

50

75

100

125

150

175

Gerber files for the ASEK37800 evaluation board are available

for download from the Allegro website. See the technical docu-

ꢁꢃꢄient ꢅeꢃperature ꢀ°Cꢂ

Figure 32: Maximum Continuous Current at a Given TA ments section of the ACS37800 device webpage.

38

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

ALLEGRO [ ALLEGRO MICROSYSTEMS ]

ALLEGRO [ ALLEGRO MICROSYSTEMS ]