Window Material

ensures that the window will not

alter either the radiation pattern

of the LED, or the receive pattern

of the photodiode.

window, the radius of the front

and back curves, and the distance

from the back surface to the

transceiver. Once these items are

known, a lens design can be

Almost any plastic material will

work as a window material.

Polycarbonate is recommended.

The surface finish of the plastic

should be smooth, without any

texture. An IR filter dye may be

used in the window to make it

look black to the eye, but the

total optical loss of the window

should be 10 percent or less for

best optical performance. Light

loss should be measured at 875

nm.

If the window must be curved for

mechanical or industrial design

reasons, place the same curve on

the back side of the window that

has an identical radius as the

front side. While this will not

completely eliminate the lens

effect of the front curved surface,

it will significantly reduce the

effects. The amount of change in

the radiation pattern is dependent

upon the material chosen for the

made which will eliminate the

effect of the front surface curve.

The following drawings show the

effects of a curved window on the

radiation pattern. In all cases,

the center thickness of the

window is 1.5 mm, the window is

made of polycarbonate plastic,

and the distance from the

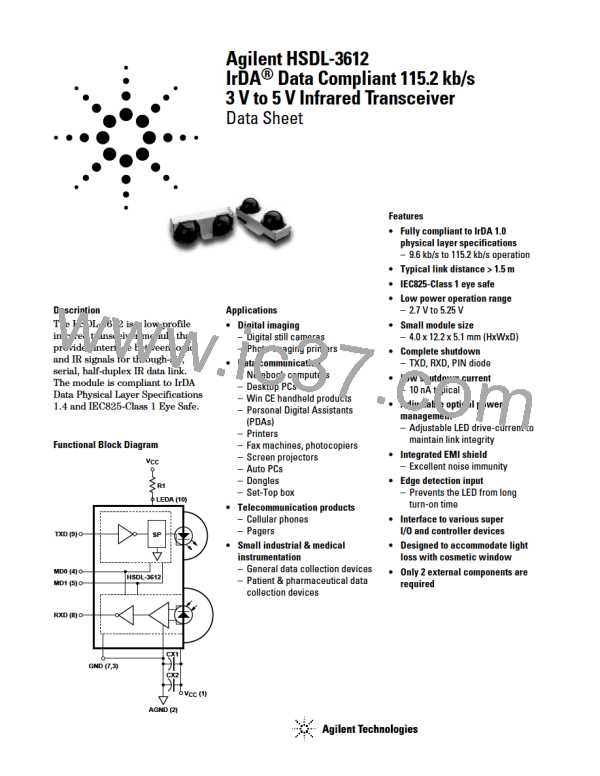

Shape of the Window

From an optics standpoint, the

window should be flat. This

transceiver to the back surface of

the window is 3 mm.

Flat Window

Curved Front and Back

Curved Front, Flat Back

(First choice)

(Second choice)

(Do not use)

24

AGILENT [ AGILENT TECHNOLOGIES, LTD. ]

AGILENT [ AGILENT TECHNOLOGIES, LTD. ]