Data Sheet

ADM3055E/ADM3057E

Surface Tracking

Calculation and Use of Parameters Example

Surface tracking is addressed in electrical safety standards by

setting a minimum surface creepage based on the working

voltage, the environmental conditions, and the properties of the

insulation material. Safety agencies perform characterization

testing on the surface insulation of components, allowing the

components to be categorized in different material groups.

Lower material group ratings are more resistant to surface

tracking and can therefore provide adequate lifetime with

smaller creepage. The minimum creepage for a given working

voltage and material group is in each system level standard and

is based on the total rms voltage across the isolation, pollution

degree, and material group. See Table 3 for the material group

and creepage information for the ADM3055E and the ADM3057E

isolated CAN transceivers.

The following example frequently arises in power conversion

applications. Assume that the line voltage on one side of the

isolation is 240 VAC RMS, and a 400 VDC bus voltage is present on

the other side of the isolation barrier. The isolator material is

polyimide. To establish the critical voltages used to determine

the creepage, clearance, and lifetime of a device, see Figure 34

and the equations that follow.

V

AC RMS

V

V

V

DC

PEAK

RMS

Insulation Wear Out

The lifetime of insulation caused by wear out is determined by

the thickness, material properties, and the voltage stress applied

across the insulation. It is important to verify that the product

lifetime is adequate at the application working voltage. The

working voltage supported by an isolator for wear out may not

be the same as the working voltage supported for tracking. The

working voltage applicable to tracking is specified in most

standards.

TIME

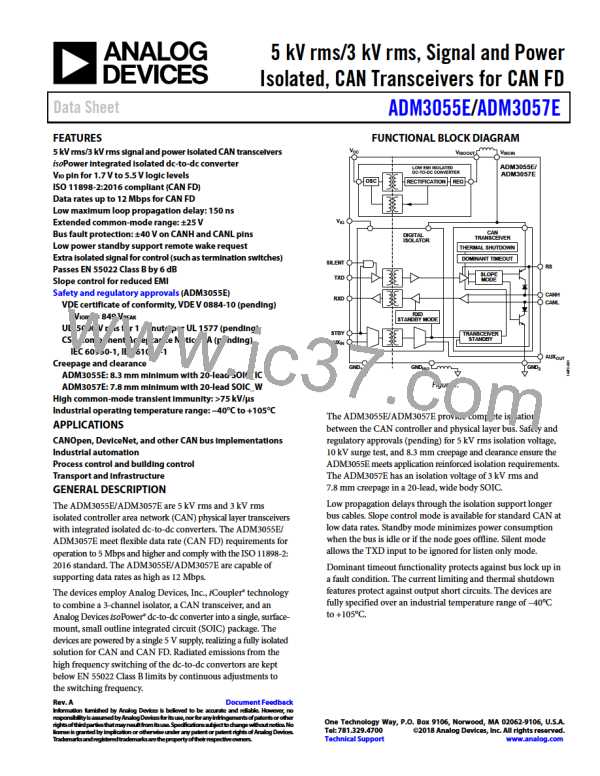

Figure 34. Critical Voltage Example

The working voltage across the barrier from Equation 1 is

2

VRMS = VAC

2 +VDC

RMS

VRMS = 2402 + 4002

RMS = 466 V

Testing and modeling show that the primary driver of long-term

degradation is displacement current in the polyimide insulation,

causing incremental damage. The stress on the insulation can be

divided into broad categories, such as dc stress and ac component,

time varying voltage stress. DC stress causes little wear out because

there is no displacement current, whereas ac component, time

varying voltage stress causes wear out.

V

Use this VRMS value as the working voltage in conjunction with

the material group and pollution degree to determine the

creepage required by a system standard.

To determine if the lifetime is adequate, obtain the time varying

portion of the working voltage. To obtain the ac rms voltage,

use Equation 2.

The ratings in certification documents are typically based on

60 Hz sinusoidal stress to reflect isolation from the line voltage.

However, many practical applications have combinations of 60 Hz

ac and dc across the barrier, as shown in Equation 1. Because

only the ac portion of the stress causes wear out, the equation

can be rearranged to solve for the ac rms voltage, as shown in

Equation 2. For insulation wear out with the polyimide materials

used in these products, the ac rms voltage determines the

product lifetime.

2

VAC

VAC

= VRMS2 −VDC

RMS

=

4662 − 4002

RMS

VAC RMS = 240 VRMS

In this case, the ac rms voltage is simply the line voltage of

240 VRMS. This calculation is more relevant when the waveform is

not sinusoidal. The calculated ac rms voltage is compared to the

limits for the working voltage in Table 11 for the expected

lifetime of the device, which is less than a 60 Hz sine wave, and

is well within the limit for a 50-year service life.

2

VRMS = VAC

2 +VDC

(1)

RMS

or

2

VAC

= VRMS2 −VDC

(2)

RMS

The dc working voltage limit is set by the creepage of the

package as specified in IEC 60664-1. This value can differ for

specific system level standards.

where:

V

V

V

RMS is the total rms working voltage.

AC RMS is the time varying portion of the working voltage.

DC is the dc offset of the working voltage.

Rev. A | Page 23 of 24

ADI [ ADI ]

ADI [ ADI ]