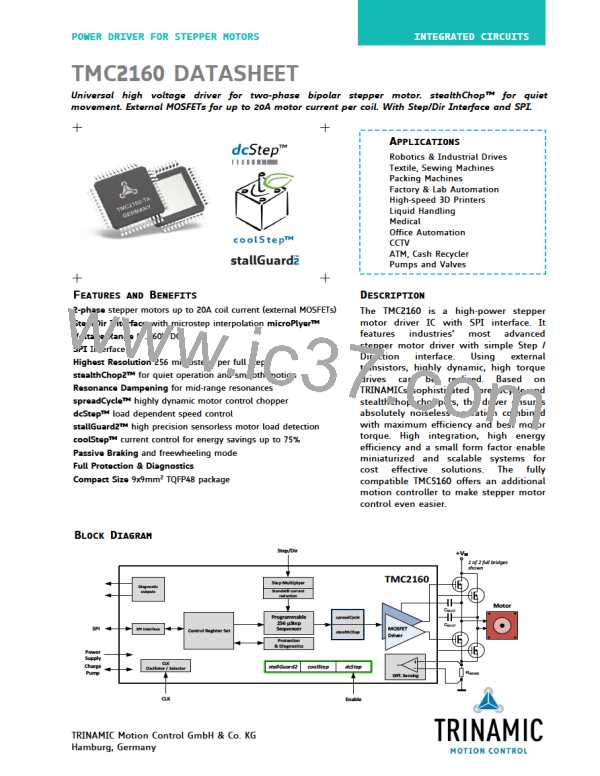

TMC2160 DATASHEET (Rev. 1.02 / 2018-NOV-19)

9

spreadCycle is an advanced cycle-by-cycle chopper mode. It offers smooth operation and good

resonance dampening over a wide range of speed and load. The spreadCycle chopper scheme

automatically integrates and tunes fast decay cycles to guarantee smooth zero crossing performance.

Benefits of using stealthChop2:

-

-

-

-

Significantly improved microstepping with low cost motors

Motor runs smooth and quiet

Absolutely no standby noise

Reduced mechanical resonance yields improved torque

1.7 stallGuard2 – Mechanical Load Sensing

stallGuard2 provides an accurate measurement of the load on the motor. It can be used for stall

detection as well as other uses at loads below those which stall the motor, such as coolStep load-

adaptive current reduction. This gives more information on the drive allowing functions like

sensorless homing and diagnostics of the drive mechanics.

1.8 coolStep – Load Adaptive Current Control

coolStep drives the motor at the optimum current. It uses the stallGuard2 load measurement

information to adjust the motor current to the minimum amount required in the actual load situation.

This saves energy and keeps the components cool.

Benefits are:

-

-

-

-

Energy efficiency

Motor generates less heat

Less or no cooling

power consumption decreased up to 75%

improved mechanical precision

improved reliability

Use of smaller motor

less torque reserve required → cheaper motor does the job

Figure 1.4 shows the efficiency gain of a 42mm stepper motor when using coolStep compared to

standard operation with 50% of torque reserve. coolStep is enabled above 60RPM in the example.

0,9

Efficiency with coolStep

0,8

0,7

0,6

0,5

0,4

0,3

0,2

0,1

0

Efficiency with 50% torque reserve

Efficiency

0

50

100

150

200

250

300

350

Velocity [RPM]

Figure 1.4 Energy efficiency with coolStep (example)

1.9 dcStep – Load Dependent Speed Control

dcStep allows the motor to run near its load limit and at its velocity limit without losing a step. If the

mechanical load on the motor increases to the stalling load, the motor automatically decreases

velocity so that it can still drive the load. With this feature, the motor will never stall. In addition to

the increased torque at a lower velocity, dynamic inertia will allow the motor to overcome mechanical

overloads by decelerating. dcStep directly integrates with the ramp generator, so that the target

position will be reached, even if the motor velocity needs to be decreased due to increased

mechanical load. A dynamic range of up to factor 10 or more can be covered by dcStep without any

www.trinamic.com

TRINAMIC [ TRINAMIC MOTION CONTROL GMBH & CO. KG. ]

TRINAMIC [ TRINAMIC MOTION CONTROL GMBH & CO. KG. ]