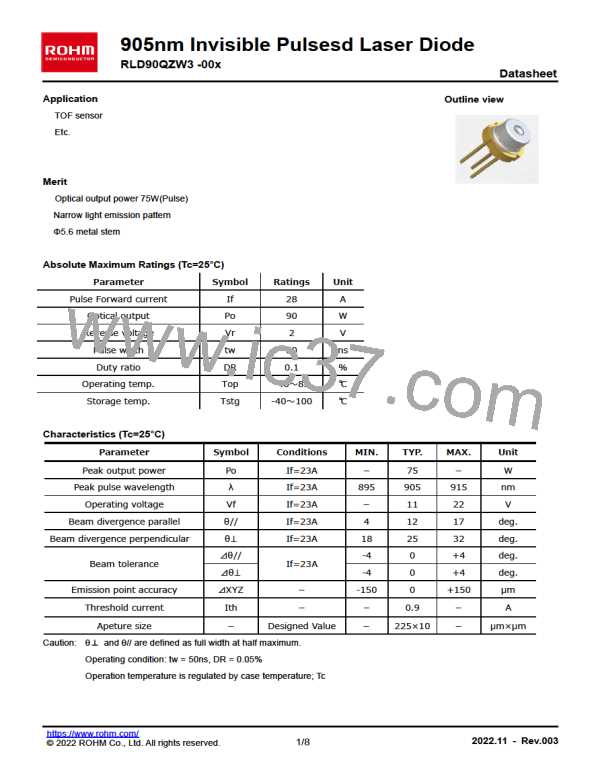

RLD90QZW3 -00x

Datasheet

Operation notes on use

This device is classified as a class Ⅳ laser product, emitting invisible laser radiation.

Direct exposure should be avoid and never look at the emitting surface.

1) Absolute maximum ratings

If an excessively flows in a laser diode, a large optical output will occur and the emitting facet may sustain damage. This

optical damage can occur even with momentary over-current. For this reason, absolute maximum ratings which must not be

exceeded even momentarily have been established. Exercise particular caution with respect to the drive voltage supply and

static electricity. We guarantee use within the absolute maximum ratings. These ratings are established for a case

temperature of 25°C. As the temperature of laser diode increases, its maximum output will decrease and the operating

range will shrink. Even when operated within the absolute maximum ratings, operation at high temperature will result in a

shorter life than operation at low temperature. For this reason, the design should include sufficient margin for heat radiation

and light output.

2) Heat radiation conditions

Like other semiconductors, prolonged operation of a laser diode will cause heat to build up at junctions and increased case

temperature. For this reason, attach aluminum (or other) heat sinks (at least 30x30x3mm) to the stem of the laser.

3) Protection against damage due to electrostatic discharge and other current surges

Electrostatic discharge and other current surges can cause deterioration and damage in laser diode, resulting in reduced

reliability. We advise talking the following protective measures.

①

②

Ground the device and circuits. Install surge filters, surge reduction transformers, or other electrostatic discharge

protectors in the power supply inputs.

When working with laser diodes wear anti-static clothing, including footwear and caps. Grounded wrist straps should

always be worn while working with laser diodes, and the trap should be grounded through a 1Mohm resistance.

Use anti-static containers for transport and storage.

③

④

Laser deterioration and damage can occur due to excessive current spikes when the power is turned on or off. Design

circuits to avoid the generation of excessive current spikes.

⑤

Inductive surge near equipment that emits high-frequency EMI can damage or destroy lasers. Avoid using lasers near

fluorescent lamps or other of EMI emissions.

4) Soldering

Use a grounded soldering iron to solder laser leads. Solder at a temperature of no more than 350°C for a maximum of 3

seconds, at a point at least 2mm from the root of the leads.

Please be careful to below points.

①

The adhesiveness of the die-bonding paste dramatically declines in high temperature, thus the package temperature

must be observed with extreme care at all times. Please avoid heating the whole package such as reflow soldering.

It is recommended to heat only one lead frame at a time. (Please avoid heating multiple leads simultaneously.)

Heating the lead frame will cause the whole package temperature to rise thus it is recommended to release the

package heat by heat sink during soldering.

②

③

④

It is recommended to solder the GND lead first to restrain the heat conduction from the lead frame.

5) In the use of the glue

There is the possibility that the volatilization component of the glue exerts the influence on the characteristic of laser diode.

Please use it after it confirm sufficiently.

6) Handling packages

Packages must not be dropped or subjected to excessive pressure. In the forming processing, be careful not to add stress

to the inner leads and cut wires. Never touch the glass parts of the laser. A damaged or dirtied glass parts will impair the

performance of the laser.

7) Safety

It is extremely dangerous to look, either directly or through a lens, at the laser beam emitted from a laser diode. Use a TV

camera or other similar device to adjust the optical axis.

https://www.rohm.com/

© 2022 ROHM Co., Ltd. All rights reserved.

2022.11 - Rev.003

7/8

ROHM [ ROHM ]

ROHM [ ROHM ]