Daattaasshheeeett

BHxxMA3 series

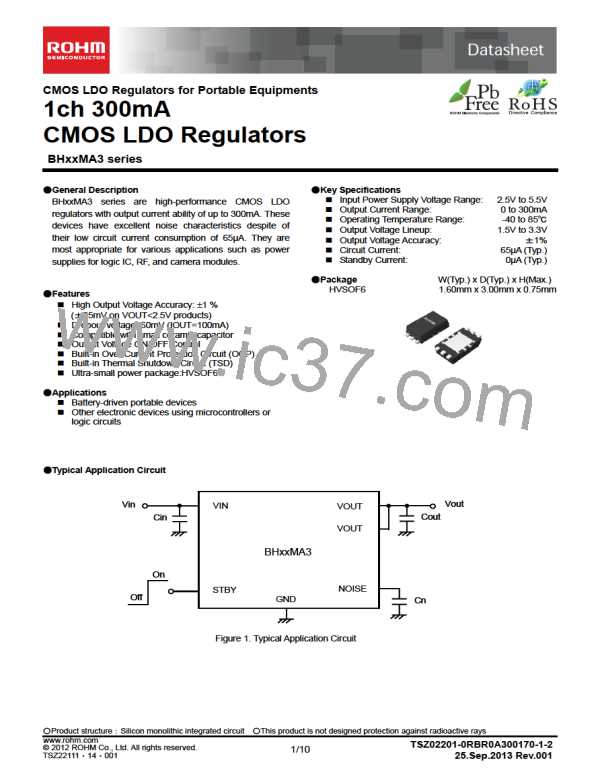

●About input/output capacitor

Capacity value of ceramic capacitor - DC bias characteristics

(Example)

It is recommended that an input capacitor is placed near pins

between the VCC pin and GND as well as an output capacitor

between the output pin and GND. The input is valid when the

power supply impedance is high or when the PCB trace has

significant length. For the output capacitor, the greater the

capacitance, the more stable the output will be depending on

the load and line voltage variations. However, please check the

actual functionality of this capacitor by mounting it on a board

for the actual application. Ceramic capacitors usually have

different, thermal and equivalent series resistance

characteristics, and may degrade gradually over continued

use.

10-V withstand voltage

B1characteristics

GRM188B11A105KA61D

10

0

10-V withstand voltage

B characteristics

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

6.3-V withstand voltage

B characteristics

10-V withstand voltage

F characteristics

4-V withstand voltage

X6S characteristics

10-V withstand voltage

F characteristics

0

0.5

1

1.5

2

2.5

3

3.5

4

For additional details, please check with the manufacturer,

and select the best ceramic capacitor for your application

DC Bias Voltage [V]

Figure 11. Capacity-bias characteristics

Cout=1.0μF,Cin=1.0μF,Temp=+25℃

●Equivalent Series Resistance (ESR) of a Ceramic Capacitor

100

Capacitors generally have ESR (equivalent series resistance) and it

operates stably in the ESR-IOUT area shown on the right. Since

ceramic capacitors, tantalum capacitors, electrolytic capacitors, etc.

generally have different ESR, please check the ESR of the capacitor to

be used and use it within the stability area range shown in the right

graph for evaluation of the actual application.

10

1

Stable region

0.1

0.01

0

50

100

150

200

250

300

Output CurrentꢀIOUTꢀ[mA]

Figure 12. Stable region (example)

●Power Dissipation (Pd)

As for power dissipation, an estimate of heat reduction characteristics and internal power consumption of IC are shown, so

please use these for reference. Since power dissipation changes substantially depending on the implementation conditions

(board size, board thickness, metal wiring rate, number of layers and through holes, etc.), it is recommended to measure Pd

on a set board. Exceeding the power dissipation of IC may lead to deterioration of the original IC performance, such as

causing the operation of the thermal shutdown circuit or reduction in current capability. Therefore, be sure to prepare

sufficient margin within power dissipation for usage.

Calculation of the maximum internal power consumption of IC (PMAX)

PMAX=(VIN-VOUT)×IOMAX

Where : VIN=Input voltage

VOUT= Output voltage IOMAX: Maximum output current

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

0.68W

Standard ROHM

board

* Please design the margin so that

PMAX becomes is than Pd (PMAX<Pd)

within the usage temperature range

85

0

25

50

75

100

125

Ta (℃)

Figure 13.HVSOF6 Power dissipation heat reduction characteristics (Reference)

www.rohm.com

TSZ02201-0RBR0A300170-1-2

25.Sep.2013 Rev.001

© 2012 ROHM Co., Ltd. All rights reserved.

7/10

TSZ22111・15・001

ROHM [ ROHM ]

ROHM [ ROHM ]