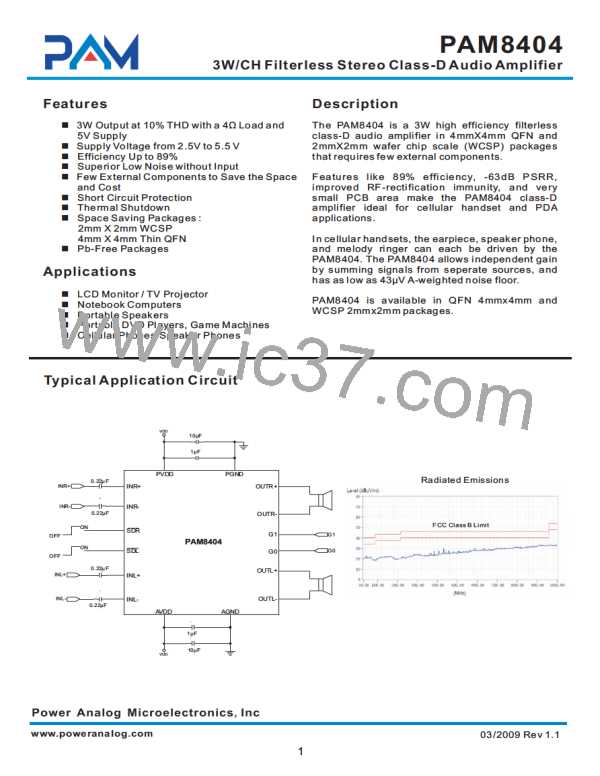

PAM8404

3W/CH Filterless Stereo Class-D Audio Amplifier

Application Information

Gain Settin

For this reason, a low-leakage tantalum or

ceramic capacitor is the best choice. When

The gain of PAM8404 can be selected as 6,12,18

or 24 dB utilizing the G0 and G1 gain setting pins.

The gains showed in the following table are

realized by changing the input resistors inside the

amplifier. The input impedance changes with the

gain setting.

polarized capacitors are used, the positive side of

the capacitor should face the amplifier input in

most applications as the DC level is held at VDD/2,

which is likely higher than the source DC level.

Please note that it is important to confirm the

capacitor polarity in the application.

If the corner frequency is within the audio band,

the capacitors should have a tolerance 10% or

better, because any mismatch in capacitance

cause an impedance mismatch at the corner

frequency and below.

Table-1: Gain Setting

G1 G0 GAIN GAIN INPUT IMPEDANCE

(V/V) (dB)

(kΩ)

28.1

17.3

9.8

0

0

1

1

0

1

0

1

2

4

6

12

18

24

Decoupling Capacitor (CS)

8

The PAM8404 is a high-performance CMOS audio

amplifier that requires adequate power supply

decoupling to ensure the output total harmonic

distortion (THD) as low as possible. Power supply

decoupling also prevents the oscillations causing

by long lead length between the amplifier and the

speaker.

16

5.2

For optimal performance the gain should be set to

2x (Ri=150kΩ). Lower gain allows the PAM8404

to operate at its best, and keeps a high voltage at

the input making the inputs less susceptible to

noise. In addition to these features, lower value of

Gain minimizes pop noise.

The optimum decoupling is achieved by using two

different types of capacitors that target on

different types of noise on the power supply

leads. For higher frequency transients, spikes, or

digital hash on the line, a good low equivalent-

series-resistance (ESR) ceramic capacitor,

typically 1μF, is placed as close as possible to the

device each VDD and PVDD pin for the best

operation. For filtering lower frequency noise

signals, a large ceramic capacitor of 10μF or

greater placed near the audio power amplifier is

recommended.

Input Capacitors (Ci )

In the typical application, an input capacitor, Ci, is

required to allow the amplifier to bias the input

signal to the proper DC level for optimum

operation. In this case, Ci and the input

impedance Ri form a high-pass filter with the

corner frequency determined by the follow

equation:

1

fC =

2pRiCi

(

)

How to Reduce EMI

It is important to consider the value of Ci as it

directly affects the low frequency performance of

the circuit. When Ri is 28.1kΩ and the

specification calls for a flat bass response are

down to 200Hz, the equation is reconfigured as

follows:

Most applications require a ferrite bead filter for

EMI elimination as shown at Figure 1. The ferrite

filter reduces EMI of around 1MHz and higher.

When selecting a ferrite bead, choose one with

high impedance at high frequencies and low

impedance at low frequencies.

1

Ci =

Ferrite Bead

OUT+

2pR

ifc

(

)

When input resistance variation is considered,

the Ci is 28nF, so one would likely choose a value

of 33nF. A further consideration for this capacitor

is the leakage path from the input source through

the input network (Ci, Ri + Rf) to the load. This

leakage current creates a DC offset voltage at the

input to the amplifier that reduces useful

headroom, especially in high gain applications.

220pF

Ferrite Bead

OUT-

220pF

Figure 1: Ferrite Bead Filter to Reduce EMI

Power Analog Microelectronics,Inc

www.poweranalog.com

03/2009 Rev 1.1

14

PAM [ POWER ANALOG MICOELECTRONICS ]

PAM [ POWER ANALOG MICOELECTRONICS ]