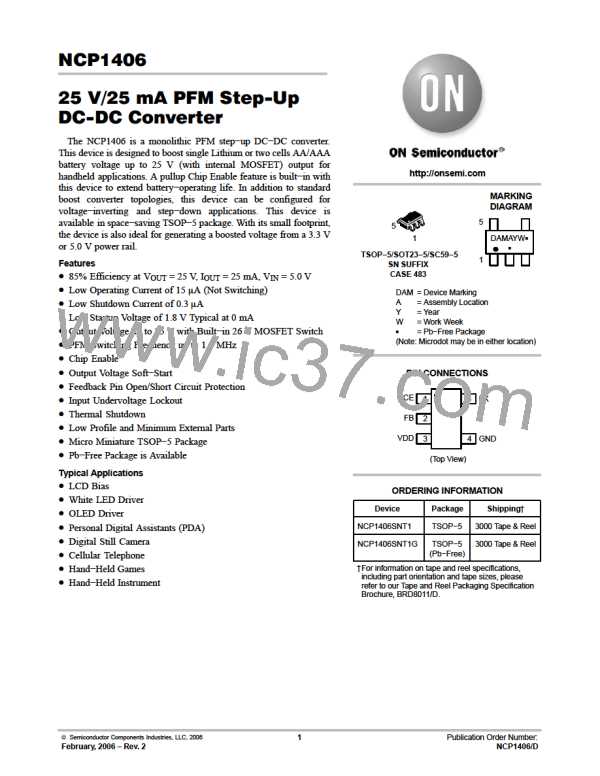

NCP1406

Input Capacitor

1% tolerance resistors should be used for both R1 and R2

for better VOUT accuracy.

The input capacitor stabilizes the input voltage and

minimizes peak current ripple from the power source. The

capacitor should be connected directly to the inductor pin

where the input voltage is applied in order to effectively

smooth the input current ripple and voltage due to the

inductor current ripple. The input capacitor is also used to

decouple the high frequency noise from the VDD supply to

the internal control circuit; therefore, the capacitor should

be placed close to the VDD pin. For some particular

applications, separate decoupling capacitors should be

provided and connected directly to the VDD pin for better

decoupling effect. A larger input capacitor can better

reduce ripple current at the input. By reducing the ripple

current at the input, the converter efficiency can be

improved. In general, a 4.7 mF to 22 mF ceramic input

capacitor is sufficient for most applications. X5R and X7R

type ceramic capacitors are recommended due to their

good capacitance tolerance and stable temperature

behavior.

Feedforward Capacitor

A feedforward capacitor is required to add across the

upper feedback resistor to avoid double pulsing or group

pulsing at the switching node which will cause larger

inductor ripple current and higher output voltage ripple.

With adequate feedforward capacitance, evenly distributed

single pulses at the switching node can be achieved. The

range of the capacitor value is from 5.0 pF to 200 pF for

most applications. For NCP1406, the lower the switching

frequency, the larger the feedforward capacitance is

needed; besides, the higher the output voltage, the larger

the feedforward capacitance is required. For the initial trial

value of the feedforward capacitor, the following equation

can be used; however, the actual value needs fine tuning:

1

C

FF

[

f

SW(Load)

2 p

R1

20

Output Voltage Higher than 25 V

Output Capacitor

The NCP1406 can be used to generate output voltage

higher than 25 V by adding an external high voltage N−Ch

MOSFET in series with the internal MOSFET switch as

shown in Figure 51. The drain−to−source breakdown

voltage of the external MOSFET must be at least 1.0 V

higher than the output voltage. The diode D2 connected

across the gate and the source of the external MOSFET

helps the external MOSFET to turn off and ensures that

most of the voltage drops across the external MOSFET

during the switch−off period. Since the high voltage

external MOSFET is in series with the internal MOSFET,

higher break down voltage is achieved but the current

capability is not increased.

There is an alternative application circuit shown in

Figure 53 which can output voltage up to 30 V. For this

circuit, a diode−capacitor charge−pump voltage doubler

constructed by D2, D3 and C1 is added. During the internal

MOSFET switch−on time, the LX pin is shorted to ground

and D2 will charge up C1 to the stepped up voltage at the

cathode of D1. During the MOSFET switch−off time, the

voltage at VOUT will be almost equal to the double of the

voltage at the cathode of D1. The VOUT is monitored by the

FB pin via the resistor divider and can be set by the resistor

values. Since the maximum voltage at the cathode of D1 is

15 V, the maximum VOUT is 30 V. The value of C1 can be in

the range of 0.47 mF to 2.2 mF.

The output capacitor is used for sustaining the output

voltage when no current is delivering from the input, and

smoothing the ripple voltage. Ceramic capacitors should

be used for the output capacitor due to their low ESR at high

switching frequency and low profile in physical size. In

general, a 3.3 mF to 22 mF ceramic capacitor should be

appropriate for most applications. X5R and X7R type

ceramic capacitors are recommended due to their good

capacitance tolerance and temperature coefficient, while

Y5V type ceramic capacitors are not recommended since

both their capacitance tolerance and temperature

coefficient are too large. The output voltage ripple and

switching frequency at nominal load current can be

calculated by the following equations:

I

C

I

L

OUT

OUT SW(Load)

1

PK

ǒ

Ǔ

V

ripple

+

*

f

V

) V −V

IN

OUT

D

* (I −I

PK OUT

) ESR

2I

(V

) V −V

)

IN

OUT OUT

2

D

f

+

SW(Load)

I

L

PK

Where I

is the nominal load current, C

is the

OUT

OUT

selected output capacitance, I

is the peak inductor

PK

current, L is the selected inductance, V

is the output

OUT

voltage, V is the Schottky diode forward voltage, V is

D

IN

the input voltage, ESR is the ESR of the output capacitor.

Negative Voltage Generation

The NCP1406 can be used to produce a negative voltage

output by adding a diode−capacitor charge−pump circuit

(D2, D3, and C1) to the LX pin as shown in Figure 50. The

feedback voltage resistor divider is still connected to the

positive output to monitor the positive output voltage and

a small value capacitor is used at C2. When the internal

MOSFET switches off, the voltage at the LX pin charges

up the capacitor through diode D2. When the MOSFET

Feedback Resistors

To achieve better efficiency at light load, a high

impedance feedback resistor divider should be used.

Choose the lower resistor R2 value from the range of 10 kW

to 200 kW. The value of the upper resistor R1 can then be

calculated from the equation below:

V

1.19

OUT

+ R ǒ * 1Ǔ

R

1

2

http://onsemi.com

14

ONSEMI [ ONSEMI ]

ONSEMI [ ONSEMI ]