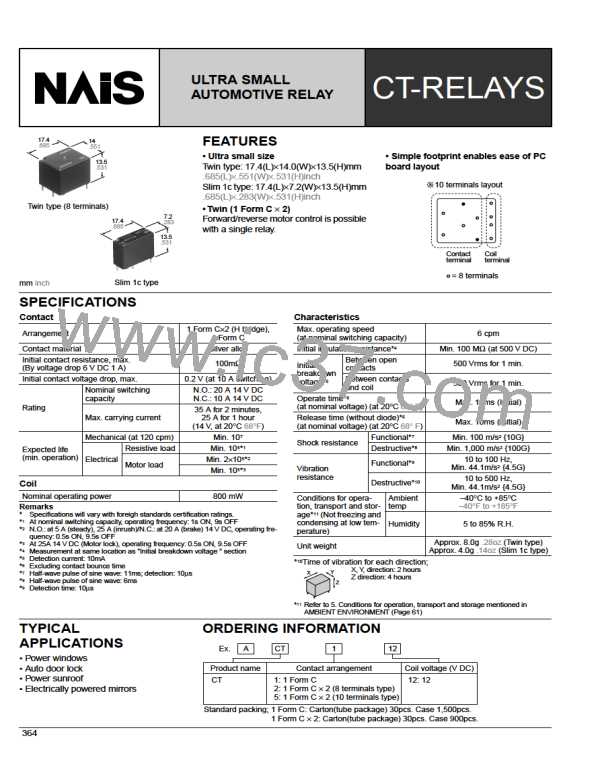

CT

3. Slim 1c type

mm inch

PC board pattern (Bottom view)

17.4

.685

7.2

.283

3-1.4 dia.

3-.055 dia.

9.5

13.5

.531

.374

6

0.4

.016

Max. 1.0

.039

.236

4.3

.169

3.15

.124

3.5

.138

2-1.1 +0.1 dia.

*A

0

0.65

.026

2-.043 +0.04 dia.

15

.591

0

0.4

.016

0.8

.031

1

.039

1

.039

0.4

0.4

0.3

.012

Sealed by epoxy resin

.016 .016

Tolerance: ±0.1±.004

9.5

.374

1.25

.049

Pre-soldering

6

.236

Schematic (Bottom view)

1

.039

4.3

.169

Dimension:

Max. 1mm .039 inch:

1 to 3mm .039 to .118 inch: ±0.2 ± .008

Min. 3mm .118 inch: ±0.3 ± .012

Tolerance

±0.1 ± .004

3.15

.124

JAPAN

NO

COIL

NC

COM

1.45

.057

0.65

.006

15

.591

* Dimensions (thickness and width) of terminal specified in this catalog is measured before pre-soldering.

Intervals between terminals is measured at A surface level.

EXAMPLE OF CIRCUIT

NO

Forward/reverse control circuits of DC

COM

12 V DC

motor for power windows

Tr 1

NC

M

NO

NC

COM

Tr 2

M Power window motor

REFERENCE DATA

1-(1). Coil temperature rise (at 20°C 68°F)

1-(2). Coil temperature rise (at 85°C 185°F)

Sample: ACT212, 3pcs

Sample: ACT212, 3pcs

Contact carrying current: 0A, 10A, 20A

Contact carrying current: 0A, 10A, 20A

140

140

20A

120

120

20A

10A

0A

100

100

10A

0A

80

80

60

60

40

20

0

40

20

0

12

14

16

12

14

16

Coil applied voltage, V

Coil applied voltage, V

2-(1). Electrical life test (Motor load)

2-(2). Electrical life test (Motor lock)

Tested sample: ACT212, 3pcs.

Load: 5A steady, Inrush 25A, 14V DC

Operating frequency: ON 0.5s, OFF 9.5s

Tested sample: ACT212, 3pcs.

Load: 25A, 14V DC

Operating frequency: ON 0.5s, OFF 9.5s

10

10

8

Circuit

8

Tested sample

Max.

X

Min.

Pick-up voltage

Drop-out voltage

Pick-up voltage

Max.

X

Min.

6

6

4

4

M

Drop-out voltage

Max.

X

Min.

Max.

X

Min.

2

2

0

0

0

10

0

10

20

4

4

No. of operations, × 10

No. of operations, × 10

For Cautions for use, see Relay Technical Information (Page 48 to 76).

366

9/1/2000

All Rights Reserved, © Copyright Matsushita Electric Works, Ltd.

Go To Online Catalog

NAIS [ NAIS(MATSUSHITA ELECTRIC WORKS) ]

NAIS [ NAIS(MATSUSHITA ELECTRIC WORKS) ]