APPLICATION NOTES

REGULATOR PROTECTION:

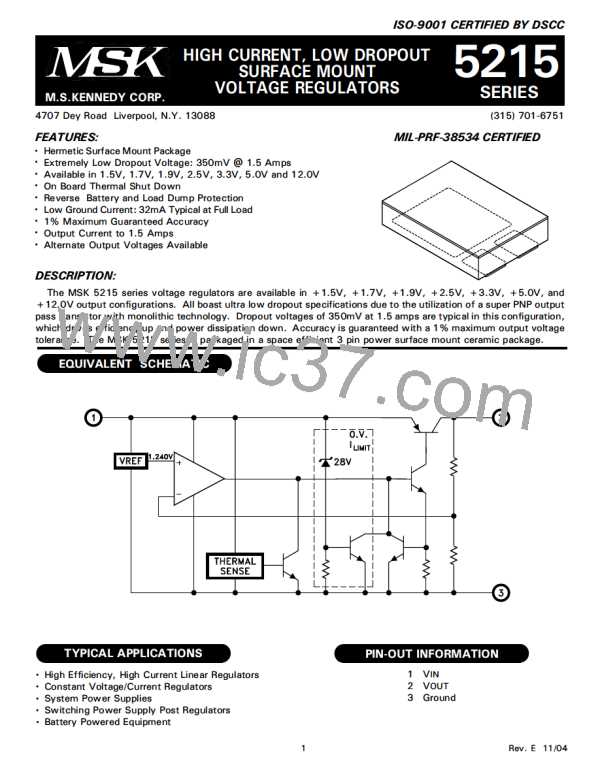

PACKAGE CONNECTIONS:

The MSK 5215 series is fully protected against re-

versed input polarity, overcurrent faults, overtemperature

conditions (Pd) and transient voltage spikes of up to 60V.

If the regulator is used in dual supply systems where the

load is returned to a negative supply, the output voltage

must be diode clamped to ground.

The MSK 5215 series are highly thermally conductive

devices and the thermal path from the package heat sink

to the internal junctions is very short. Standard surface

mount soldering techniques should be used when mount-

ing the device. Some applications may require additional

heat sinking of the device.

HEAT SINK SELECTION:

OUTPUT CAPACITOR:

The output voltage ripple of the MSK 5215 series volt-

age regulators can be minimized by placing a filter ca-

pacitor from the output to ground. The optimum value

for this capacitor may vary from one application to the

next, but a minimum of 33µF is recommended for opti-

mum performance. Transient load response can also be

improved by placing a capacitor directly across the load.

The capacitor should not be an ultra-low ESR type. Tan-

talum capacitors are best for fast load transients but

aluminum electrolytics will work fine in most applica-

tions.

To select a heat sink for the MSK 5215, the following

formula for convective heat flow may be used.

Governing Equation:

Tj = Pd x (Rθjc + Rθcs + Rθsa) + Ta

WHERE:

Tj = Junction Temperature

Pd = Total Power Dissipation

Rθjc = Junction to Case Thermal Resistance

Rθcs = Case to Heat Sink Thermal Resistance

Rθsa = Heat Sink to Ambient Thermal Resistance

Ta = Ambient Temperature

LOAD CONNECTIONS:

In voltage regulator applications where very large load

currents are present, the load connection is very impor-

tant. The path connecting the output of the regulator to

the load must be extremely low impedance to avoid af-

fecting the load regulation specifications. Any imped-

ance in this path will form a voltage divider with the load.

First, the power dissipation must be calculated as fol-

lows:

Power Dissipation = (Vin - Vout) x Iout

Next, the user must select a maximum junction tem-

perature. The absolute maximum allowable junction tem-

perature is 125°C. The equation may now be rearranged

to solve for the required heat sink to ambient thermal

resistance (Rθsa).

MINIMIZING POWER DISSIPATION:

Many applications can not take full advantage of the

extremely low dropout specifications of the regulator due

to large input to output voltage differences. The simple

circuit below illustrates a method to reduce the input

voltage at the regulator to just over the dropout specifi-

cation to keep the internal power dissipation minimized:

EXAMPLE:

An MSK 5215-3.3 is configured for Vin=+5V and

Vout=+3.3V. Iout is a continuous 1A DC level. The

ambient temperature is +25°C. The maximum desired

junction temperature is 125°C.

Rθjc = 3.5°C/W and Rθcs = 0.5°C/W typically.

Power Dissipation = (5V - 3.3V) x (1A)

= 1.7 Watts

Solve for Rθsa:

Rθsa = 125°C - 25°C - 3.5°C/W - 0.5°C/W

1.7W

[

= 54.82°C/W

]

For a given continuous maximum load of 1 amp, R1

can be selected to drop the voltage seen at the regulator

to 4V. This allows for the output tolerance and dropout

specifications. Input voltage variations (5V) also should

be included in the calculations. The resistor should be

sized according to the power levels required for the ap-

plication.

In this example, a heat sink with a thermal resistance

of no more than 54°C/W must be used to maintain a

junction temperature of no more than 125°C.

3

Rev. E 11/04

MSK [ M.S. KENNEDY CORPORATION ]

MSK [ M.S. KENNEDY CORPORATION ]