Document 528-2

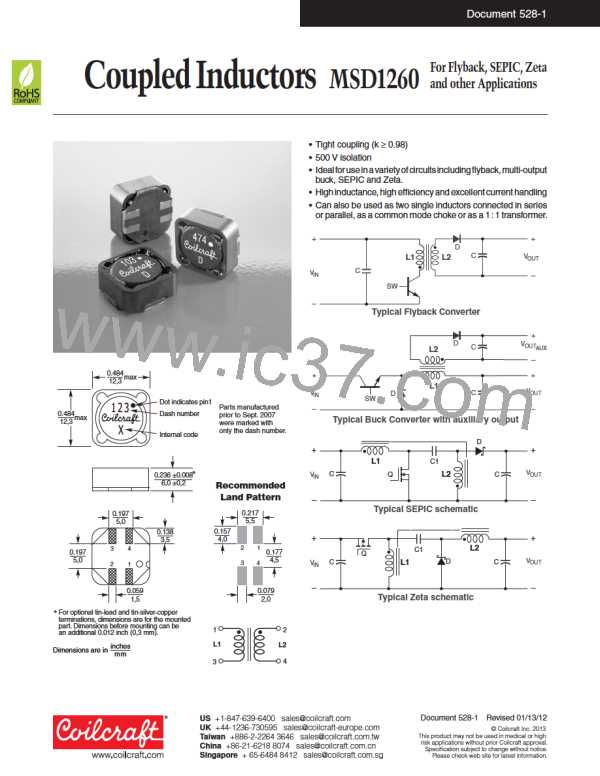

Coupled Inductors – MSD1260 Series

Irms(A)

Coupling

Leakage

Part

Inductance2

(µH)

DCRmax3

(Ohms)

SRFtyp4

(MHz)

coefficient Inductance5

Isat6

(A)

both

one

number1

typ

typ(µH)

windings7 winding8

MSD1260-472ML_

MSD1260-562ML_

MSD1260-682ML_

MSD1260-822ML_

MSD1260-103ML_

4.7 20ꢀ

5.6 20ꢀ

6.8 20ꢀ

8.2 20ꢀ

10 20ꢀ

0.036

0.040

0.048

0.052

0.060

32.0

31.0

28.0

25.0

22.0

0.98

0.98

0.98

0.98

0.99

0.20

0.20

0.24

0.25

0.26

10.3

9.66

9.21

8.55

7.40

3.16

3.00

2.75

2.63

2.45

4.47

4.24

3.88

3.72

3.46

MSD1260-123ML_

MSD1260-153ML_

MSD1260-183ML_

MSD1260-223ML_

MSD1260-273ML_

12 20ꢀ

15 20ꢀ

18 20ꢀ

22 20ꢀ

27 20ꢀ

0.074

0.085

0.097

0.116

0.124

21.0

17.6

17.0

15.0

13.6

0.99

0.99

0.99

0.98

0.99

0.28

0.32

0.40

0.68

0.50

6.86

6.09

5.30

5.01

4.66

2.21

2.06

1.93

1.76

1.70

3.12

2.92

2.73

2.49

2.41

MSD1260-333ML_

MSD1260-393ML_

MSD1260-473ML_

MSD1260-563ML_

MSD1260-683ML_

33 20ꢀ

39 20ꢀ

47 20ꢀ

56 20ꢀ

68 20ꢀ

0.134

0.142

0.174

0.198

0.216

12.7

11.7

8.7

7.6

6.1

0.99

0.99

0.99

0.99

>0.99

0.65

1.09

0.80

0.75

0.57

4.22

3.80

3.25

3.07

2.83

1.64

1.59

1.44

1.35

1.29

2.32

2.25

2.03

1.91

1.83

MSD1260-823ML_

MSD1260-104ML_

MSD1260-124KL_

MSD1260-154KL_

MSD1260-184KL_

82 20ꢀ

100 20ꢀ

120 10ꢀ

150 10ꢀ

180 10ꢀ

0.274

0.322

0.418

0.476

0.536

5.3

5.0

4.4

4.0

3.6

0.99

0.99

0.99

0.99

0.99

1.52

1.41

1.34

1.52

1.80

2.55

2.20

2.05

1.82

1.60

1.15

1.06

0.93

0.87

0.82

1.62

1.50

1.31

1.23

1.16

MSD1260-224KL_

MSD1260-274KL_

MSD1260-334KL_

MSD1260-394KL_

MSD1260-474KL_

220 10ꢀ

270 10ꢀ

330 10ꢀ

390 10ꢀ

470 10ꢀ

0.691

0.806

1.09

1.20

1.59

3.2

2.8

2.5

2.3

2.1

>0.99

>0.99

>0.99

>0.99

>0.99

1.60

2.23

2.39

3.72

2.89

1.51

1.41

1.28

1.16

1.00

0.72

0.67

0.57

0.55

0.48

1.02

0.95

0.81

0.77

0.67

MSD1260-564KL_

MSD1260-684KL_

MSD1260-824KL_

MSD1260-105KL_

560 10ꢀ

680 10ꢀ

820 10ꢀ

1000 10ꢀ

1.81

2.06

2.65

3.06

2.0

1.8

1.5

1.2

>0.99

>0.99

>0.99

>0.99

2.55

5.76

2.86

4.32

0.95

0.88

0.79

0.69

0.45

0.42

0.37

0.34

0.63

0.59

0.52

0.49

Coupled Inductor Core and Winding Loss Calculator

1. When ordering, please specify termination and packaging codes:

MSD1260-105KLD

Termination: L = RoHS compliant matte tin over nickel over phos

bronze.

This web-based utility allows you to enter frequency, peak-to-peak

(ripple) current, and Irms current to predict temperature rise and overall

losses, including core loss. Go to online calculator.

Special order: T = RoHS tin-silver-copper (95.5/4/0.5) or

S = non-RoHS tin-lead (63/37).

Core material Ferrite

Packaging: D = 13″ machine-ready reel. EIA-481 embossed plastic

tape (500 parts per full reel).

Core and winding loss Go to online calculator

Terminations RoHS compliant matte tin over nickel over phos bronze.

Other terminations available at additional cost.

B = Less than full reel. In tape, but not machine ready.

To have a leader and trailer added ($25 charge), use

code letter D instead.

Weight: 2.8 – 3.2 g

2. Inductance shown for each winding, measured at 100 kHz, 0.1 Vrms,

0 Adc on an Agilent/HP 4284A LCR meter or equivalent.When leads

are connected in parallel, inductance is the same value.When leads are

connected in series, inductance is four times the value.

3. DCR is for each winding.When leads are connected in parallel, DCR

is half the value.When leads are connected in series, DCR is twice the

value.

Ambient temperature –40°C to +85°C with Irms current, +85°C to

+125°C with derated current

Storage temperature Component: –40°C to +125°C.

Tape and reel ackaging: –40°C to +80°C

Winding-to-winding and winding-to-core isolation 500 Vrms

Resistance to soldering heat Max three 40 second reflows at

+260°C, parts cooled to room temperature between cycles

Moisture Sensitivity Level (MSL) 1 (unlimited floor life at <30°C /

85ꢀ relative humidity)

Failures in Time (FIT) / Mean Time Between Failures (MTBF)

38 per billion hours / 26,315,789 hours, calculated per Telcordia SR-332

Packaging 500/13″ reel; Plastic tape: 24 mm wide, 0.35 mm thick,

16 mm pocket spacing, 6.6 mm pocket depth

PCB washing Tested with pure water or alcohol only. For other

solvents, see Doc787_PCB_Washing.pdf.

4. SRF measured using an Agilent/HP 4191A or equivalent.When leads

are connected in parallel, SRF is the same value.

5. Leakage Inductance is for L1 and is measured with L2 shorted.

6. DC current, at which the inductance drops 30ꢀ (typ) from its value

without current. It is the sum of the current flowing in both windings.

7. Equal current when applied to each winding simultaneously that causes

a 40°C temperature rise from 25°C ambient. See temperature rise calcu-

lation.

8. Maximum current when applied to one winding that causes a 40°C

temperature rise from 25°C ambient. See temperature rise calculation.

9. Electrical specifications at 25°C.

Refer to Doc 639 “Selecting Coupled Inductors for SEPIC Applications.”

Refer to Doc 362 “Soldering Surface Mount Components” before soldering.

Document 528-2 Revised 01/13/12

US +1-847-639-6400 sales@coilcraft.com

UK +44-1236-730595 sales@coilcraft-europe.com

Taiwan +886-2-2264 3646 sales@coilcraft.com.tw

China +86-21-6218 8074 sales@coilcraft.com.cn

Singapore + 65-6484 8412 sales@coilcraft.com.sg

© Coilcraft Inc. 2013

This product may not be used in medical or high

risk applications without prior Coilcraft approval.

Specification subject to change without notice.

Please check web site for latest information.

COILCRAFT [ Coilcraft lnc. ]

COILCRAFT [ Coilcraft lnc. ]