AD8240

ADVANTAGES OF DRIVING LED LAMPS WITH CONSTANT VOLTAGE

The advantages of driving LED lamps with constant voltage are

DRIVING AUTOMOTIVE LEDS

There are two different architectures for driving LEDs in

left/right/center brake lamps, running lamps, and turn signals.

•

•

•

Low system cost

Accurate monitoring

Proven strategy

Constant Current

The most common method for driving LEDs is with a constant

current. This current can be supplied from a constant current

source or from a constant voltage source in series with a ballast

resistor. Driving LEDs without some form of ballast carries

some risk of premature LED failure due to thermal runaway in

high temperature ambient conditions.

BACKGROUND

A great variety of LED lamps are being used in automotive

applications. The most popular application is center brake

lamps. Currently, many manufacturers are developing

technology to use LEDs for left/right brake lamps, running

lamps, and turn signals. There are also plans to use high power

LEDs for forward lighting fog lamps and low beams.

For example, in the simplest application, the center brake lamp

is driven from a relatively constant voltage with brightness

controlled by a series ballast resistor. This simple driving

method has been used in a wide variety of automotive platforms

for some time. With this method, the LEDs and ballast resistors

are preselected for brightness as part of the manufacturing

strategy.

There are two fundamental types of LEDs used in these applica-

tions. The first is the low power bright LED. The second type is

the high power, extremely bright LED in the 1 W to 10 W range.

While the following information can be applied to applications

using the high power LED, or incandescent lamps, the constant

voltage method is designed for applications typically using the

low power bright LEDs. This type of LED is used in arrays that

form LED lamps.

When driving with a constant current source, LED driving

and monitoring cannot be done using two or fewer wires

(shared ground). Since the current is constant, it does not

change with partial LED failure. Instead, the current is divided

among the remaining functional LEDs, causing them to fail

prematurely at an unpredictable rate. Additionally, it is not

possible to detect partial failure by measuring the voltage

change. The voltage does not change by a detectable amount

because of the steep V/I curve exhibited by bright LEDs. When

using a constant current scheme, at least one additional wire

per lamp must be added to the harness to monitor partial or

total LED failure. Additionally, electronic modules must be

added to each lamp.

MONITORING THE LEDS

In addition to driving the LED lamp, the electronics in the

control module must include a method for monitoring partial

LED failure in the lamp. Certain factors, such as overdriving

and mechanical stress, can cause LED failures.

Auto manufacturers are using LED lamps as a way to differen-

tiate themselves and give a car a unique appearance. Several

failed LEDs in the lamp would ruin the aesthetics of the lamp.

As a result, manufacturers are demanding the ability to monitor

the LED lamps for partial failure.

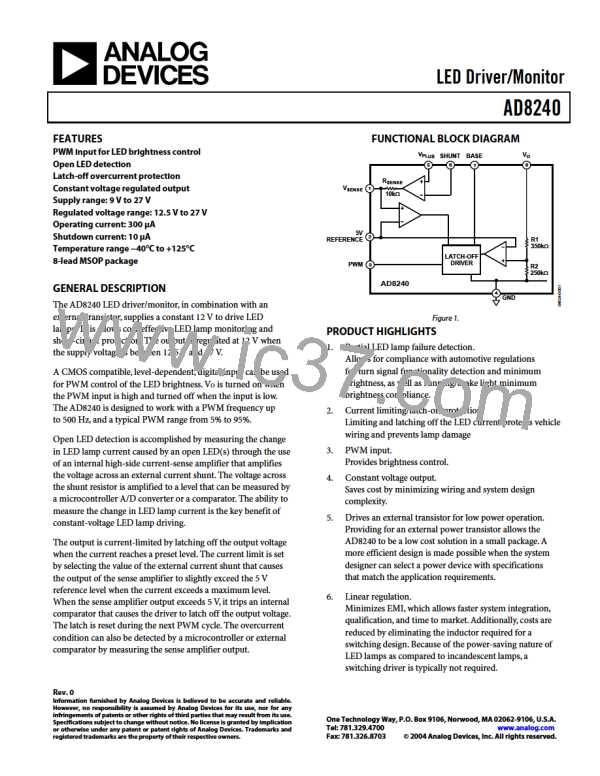

Constant Voltage

Driving LEDs with a constant voltage allows for easy, low cost

detection of partial failure, an advantage not available with a

constant-current architecture. This is because the current from

the voltage source changes in direct proportion to the number

of LEDs that have failed. This current can be measured with a

low cost shunt and an amplifier back at the body control

module. This detection scheme is implemented in the AD8240

LED driver/monitor through the use of a high-side, current-

sensing amplifier. The current is measured on the high side in

order to separate the current from those combined in the

chassis ground return or shared-wire ground return.

In addition to monitoring the LEDs for aesthetic reasons,

monitoring must also be included as a result of automotive

regulations. These regulations specify the minimum light

output of external lamps. For example, if half of the LEDs in

a particular lamp failed, the lamp would still operate, but the

light output would be insufficient to meet automotive

regulations for brightness. This concern is not an issue for

incandescent bulbs, because they are either completely on or

completely off. The ability of the LED lamp to provide some

light output in the case of partial outage, however, allows for an

extra degree of safety over incandescent lamps. Additionally,

there are automotive regulations requiring the monitoring of

the turn signals regardless of the type of light source.

Rev. 0 | Page 8 of 12

ADI [ ADI ]

ADI [ ADI ]